Amy’s Kitchenware, based in Wisconsin, wants to start a line of safe cooking glassware to rival giants like Pyrex, MadeIn, or OXO. To create her cookware Amy needs to import the main ingredients from Japan including boron trioxide, silica sand, and sodium carbonate, all of which are hazardous. She wants to increase production but was informed by her senior engineer that the oven that creates the hardened glass to make the kitchenware has broken down and needs a new part. Realizing that a shipment of the raw material is already on the way, Amy knows they don’t have enough inventory space to accept and store all the materials she ordered. Hence, she reaches out to her carrier with a question. “Is there any way we can wait on these upcoming shipments for next week? Our inventory is currently full as we wait on a piece to repair our machine.”

Depending on who is executing this move for her, Amy may be presented with several options. She could:

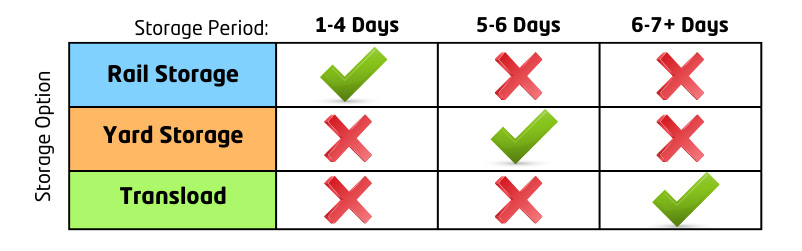

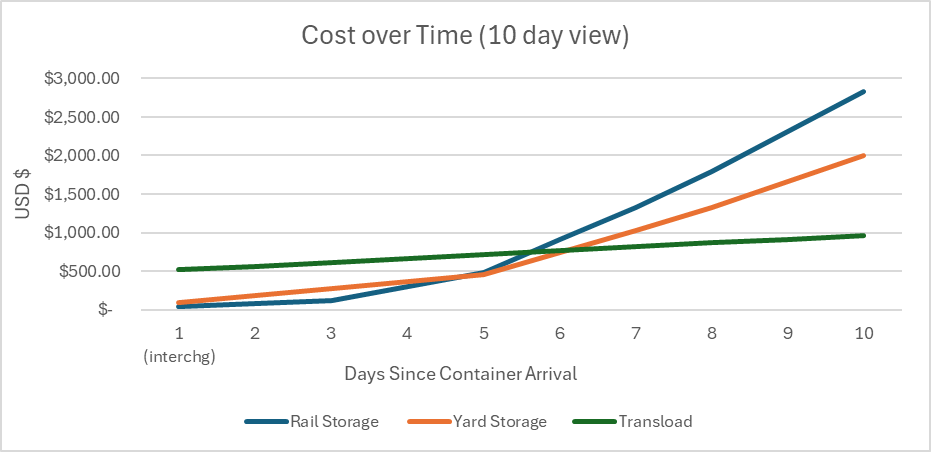

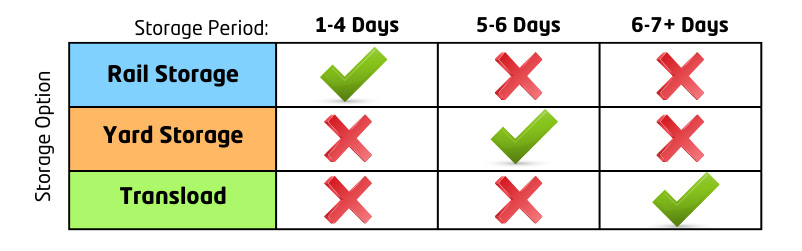

The trucking company gets back to Amy with these options and depending on the expected delay of the needed part to repair her oven, she has a choice to make. If the part will arrive in only a day or two, it’s fine to just leave the container at the rail facility and use the Rail Storage method. If the part will take 5-6 days to come in, she may consider pulling the container to a private yard if the trucking company has the ability to do so. And if the part will take weeks or even months to get in, Amy is going to hope that she can transload the raw materials!

This case demonstrates the benefits and flexibility provided by asset based trucking companies. Having facilities at key locations and other assets that can be used to adapt to any situation and keep the price to the customer low. Many trucking companies do not have these assets and therefore limit the options they can present to their customers.

Whimsy Intermodal strives to provide customers with every option we can to cater to their exact situation and deliver excellent service while keeping costs low. If you operate a business like Amy and are in the Chicago/Kansas City areas, please reach out and speak with our dispatch and pricing teams about your story and how we can help make your business the best it can be!

pricing@whimsytrucking.com

dispatch@whimsytrucking.com

(847) 690-1246

*** DISCLAIMER ***

The numbers and figures used in this case for demurrage and rail storage were pulled directly from local SSLs and Rail yards in Chicago and are subject to change at their discretion. Yard storage and transload fees are based on Whimsy Intermodal’s fees but are subject to change and are in no way a legally binding quote for business. Please reach out to Whimsy Intermodal for a quote regarding your situation.

The trucking company gets back to Amy with these options and depending on the expected delay of the needed part to repair her oven, she has a choice to make. If the part will arrive in only a day or two, it’s fine to just leave the container at the rail facility and use the Rail Storage method. If the part will take 5-6 days to come in, she may consider pulling the container to a private yard if the trucking company has the ability to do so. And if the part will take weeks or even months to get in, Amy is going to hope that she can transload the raw materials!

This case demonstrates the benefits and flexibility provided by asset based trucking companies. Having facilities at key locations and other assets that can be used to adapt to any situation and keep the price to the customer low. Many trucking companies do not have these assets and therefore limit the options they can present to their customers.

Whimsy Intermodal strives to provide customers with every option we can to cater to their exact situation and deliver excellent service while keeping costs low. If you operate a business like Amy and are in the Chicago/Kansas City areas, please reach out and speak with our dispatch and pricing teams about your story and how we can help make your business the best it can be!

pricing@whimsytrucking.com

dispatch@whimsytrucking.com

(847) 690-1246

*** DISCLAIMER ***

The numbers and figures used in this case for demurrage and rail storage were pulled directly from local SSLs and Rail yards in Chicago and are subject to change at their discretion. Yard storage and transload fees are based on Whimsy Intermodal’s fees but are subject to change and are in no way a legally binding quote for business. Please reach out to Whimsy Intermodal for a quote regarding your situation.

- Rail Storage – Let the container stay at the rail until Amy is ready to accept it.

- Yard Storage – Retrieve the container and store it at a private yard until Amy is ready to accept it.

- Transload – Retrieve the container, move the product to a carrier owned container, and store it at a private yard until Amy is ready to accept it.

- Rail yard = Chicago Rail

- Free days for SSL = interchange day + 4 days

- Free days for rail storage = interchange day + 2 days

- Private yard storage = $50/container/day

- Transload 1-time-fee = $475

- Container pulled and stored on interchange day if applicable

Rail Storage

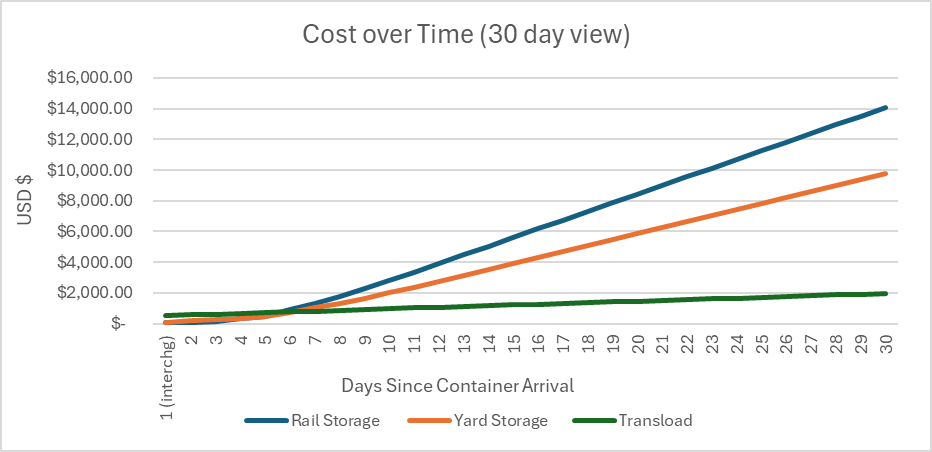

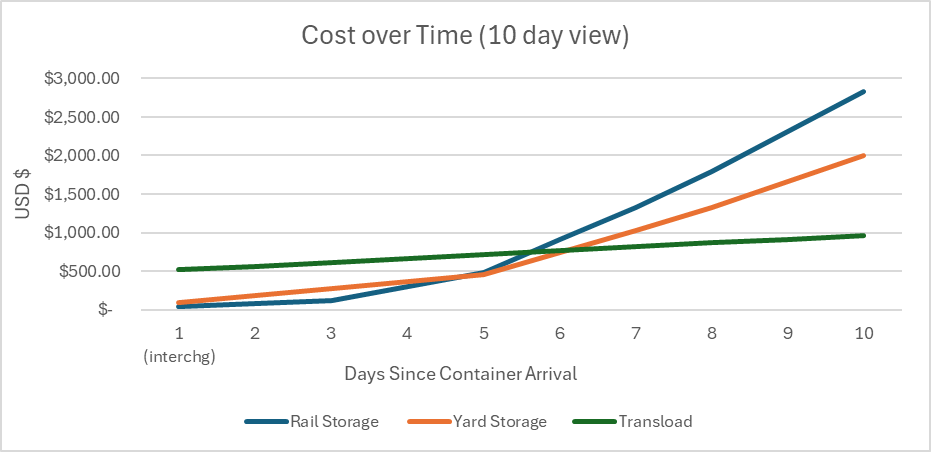

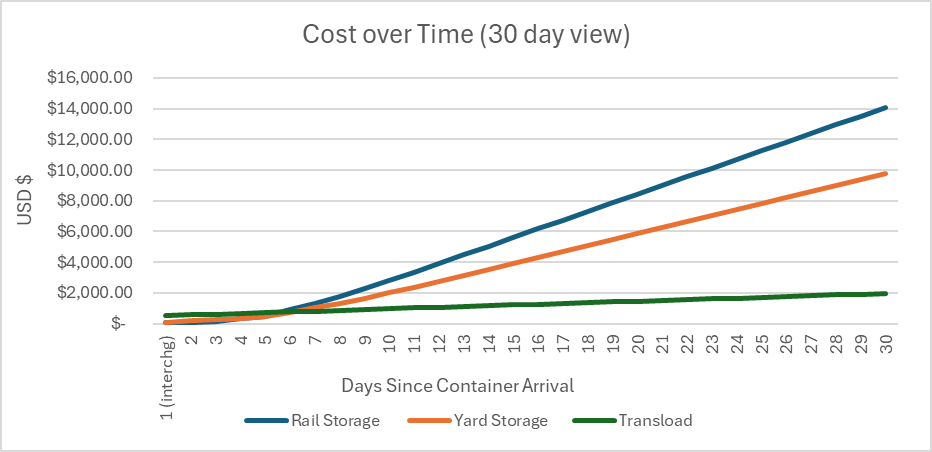

This option is represented by leaving the container at the rail yard until Amy is able to accept the delivery to her facility/warehouse. This option, represented by the dark blue line in the graphs above, is only ideal for 1-4 days of needed delay. After 3 days, rail storage starts and rapidly increases in daily price. After 5 days, SSL demurrage starts for the container being used and rapidly increases in daily price. For non-asset based trucking companies and carriers, this may be the only option for the customer regardless of the delay they need before receiving the inventory.Yard Storage

This option is represented by pulling the container from the rail yard to a privately owned yard/storage facility until Amy is able to accept the delivery to her facility/warehouse. This option, represented by the orange line in the graphs above, is ideal for 5-6 days or longer if the carrier cannot provide transload services. Unlike the rail storage example above, the container would not be charged by the rail yard to store the container there but instead would be charged a lower rate to be held at a private facility. This is only possible if the trucking company has the assets/facilities/room to do so. Despite this, and similarly to the rail storage example, the SSL demurrage on the container would start after 5 days and grow rapidly thereafter.Transload

This option is represented by pulling the container from the rail yard to a private facility while also moving the goods inside from the SSL’s container to a privately owned container until Amy is able to accept delivery to her facility/warehouse. This option, represented by the green line in the graphs above, is ideal for containers that need to be stored for 6-7+ days. Unlike both examples above, this option will never accrue rail storage or SSL demurrage meaning its per day costs are much lower as time goes on. The initial 1-time-fee for transloading makes it less suitable for short term storage, but can save thousands or tens of thousands of dollars the longer the storage is needed. This option is only available to trucking companies and transloading specific facilities that have the assets and capability to do so. The trucking company gets back to Amy with these options and depending on the expected delay of the needed part to repair her oven, she has a choice to make. If the part will arrive in only a day or two, it’s fine to just leave the container at the rail facility and use the Rail Storage method. If the part will take 5-6 days to come in, she may consider pulling the container to a private yard if the trucking company has the ability to do so. And if the part will take weeks or even months to get in, Amy is going to hope that she can transload the raw materials!

This case demonstrates the benefits and flexibility provided by asset based trucking companies. Having facilities at key locations and other assets that can be used to adapt to any situation and keep the price to the customer low. Many trucking companies do not have these assets and therefore limit the options they can present to their customers.

Whimsy Intermodal strives to provide customers with every option we can to cater to their exact situation and deliver excellent service while keeping costs low. If you operate a business like Amy and are in the Chicago/Kansas City areas, please reach out and speak with our dispatch and pricing teams about your story and how we can help make your business the best it can be!

pricing@whimsytrucking.com

dispatch@whimsytrucking.com

(847) 690-1246

*** DISCLAIMER ***

The numbers and figures used in this case for demurrage and rail storage were pulled directly from local SSLs and Rail yards in Chicago and are subject to change at their discretion. Yard storage and transload fees are based on Whimsy Intermodal’s fees but are subject to change and are in no way a legally binding quote for business. Please reach out to Whimsy Intermodal for a quote regarding your situation.

The trucking company gets back to Amy with these options and depending on the expected delay of the needed part to repair her oven, she has a choice to make. If the part will arrive in only a day or two, it’s fine to just leave the container at the rail facility and use the Rail Storage method. If the part will take 5-6 days to come in, she may consider pulling the container to a private yard if the trucking company has the ability to do so. And if the part will take weeks or even months to get in, Amy is going to hope that she can transload the raw materials!

This case demonstrates the benefits and flexibility provided by asset based trucking companies. Having facilities at key locations and other assets that can be used to adapt to any situation and keep the price to the customer low. Many trucking companies do not have these assets and therefore limit the options they can present to their customers.

Whimsy Intermodal strives to provide customers with every option we can to cater to their exact situation and deliver excellent service while keeping costs low. If you operate a business like Amy and are in the Chicago/Kansas City areas, please reach out and speak with our dispatch and pricing teams about your story and how we can help make your business the best it can be!

pricing@whimsytrucking.com

dispatch@whimsytrucking.com

(847) 690-1246

*** DISCLAIMER ***

The numbers and figures used in this case for demurrage and rail storage were pulled directly from local SSLs and Rail yards in Chicago and are subject to change at their discretion. Yard storage and transload fees are based on Whimsy Intermodal’s fees but are subject to change and are in no way a legally binding quote for business. Please reach out to Whimsy Intermodal for a quote regarding your situation.